Research and development

A LEGACY OF INNOVATION

Backed by leading orthopaedic science

In collaboration with orthopaedic surgeons, Sealy discovered that spinal health is essential to rest. To prevent backache and achieve unbroken sleep, a support system needs to maintain the body’s natural alignment. We are proud to have over 50 years of ongoing research and innovation backed by our Orthopaedic Advisory Board.

OUR RESEARCH AND DEVELOPMENT LAB

Where design is tested and perfected

Sealy conducts ongoing medical research and testing of new components, materials and construction methods in the largest NATA accredited research and development facility in the southern hemisphere. This provides our foundation for new innovation and unmatched product performance.

Every Sealy mattress is the product of 8000 hours of testing.

These are just few of the countless tests made by Sealy’s research and development team:

SUPPORT TEST

Spinal Alignment Manikin

Sealy mattresses are designed and built to specific criteria. We know from our research with orthopaedic surgeons that the best sleeping posture is the same as when we are standing upright.

We use SAM, our spinal alignment manikin, to simulate the way a human body interacts with a mattress. We measure the angles of SAM's body as he lies down.

This test helps us to create products with various comfort levels, construction methods and designs that offer correct support. All of our products and materials are rigorously tested and backed by real, industry-leading research.

COMFORT TEST

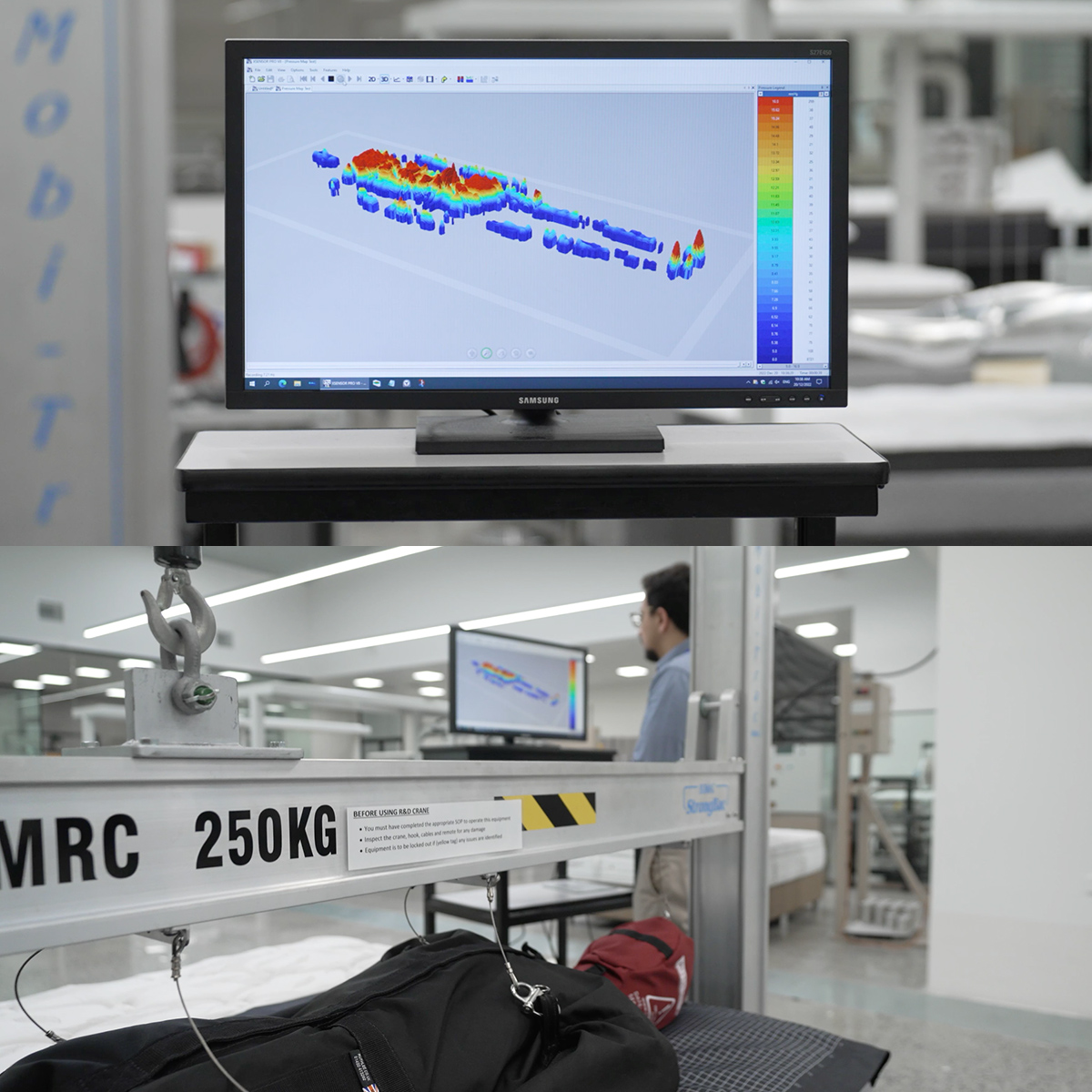

Pressure Mapping

Sealy mattresses are tested for effective comfort and support. One way that we do this is with pressure mapping. We use a sensor mat under a mannequin and, using specialist software, measure the performance of each mattress.

Your Sealy mattress is designed to support your pressure points, reducing tossing and turning throughout the night. Enjoy the benefit of quality, unbroken sleep.

DURABILITY TEST

Rollator Test

Our rollator barrel moves across a mattress 200,000 times in a single test. Weighing 110kg, it helps us to understand the impact of a person shifting and moving on a mattress.

In order to pass, the mattress must meet certain criteria so that we know it can withstand 10 years of use. We go to this effort to ensure that Sealy products look and feel the same on day 3650 as they do on day 1.

DURABILITY TEST

Robot Durability Test

One of our robots is specially designed to sit on the edge of a mattress and 'hop into bed'. The robot slides across the surface of the mattress the same way most people do at home, applying constant pressure.

Rest easy knowing that all Sealy mattresses are designed for long-lasting quality, backed by rigorous testing and a 10-year guarantee.

DURABILITY TEST

Martindale Pilling Test

At Sealy, we conduct testing on every component and material that goes into a mattress, including panel fabrics. This machine runs for 10,000 cycles, repeatedly rubbing a fabric sample across an abrasive surface. It is designed to simulate years of wear and tear.

Once the test is complete, we check for any ripping, pilling or deterioration. We do this to ensure that our panel fabrics are smooth and pristine for the full life of the mattress, whether it is at home or on the shop floor.

SOURCED AND MANUFACTURED IN AUSTRALIA

Made in Australia, made by hand

For the 9th consecutive year, Sealy has been the no.1 preferred mattress brand in Australia, with over 5 million users throughout Australia.

Made in Australia’s Sealy mattresses are made in wholly-owned factories. We use materials that are sourced from suppliers across Australia, and everything is tested to ensure we provide only the highest quality products.