- Sealy's uniqueness

- Health

- Smart tips

How Many Hours Does It Take to Test a Mattress?

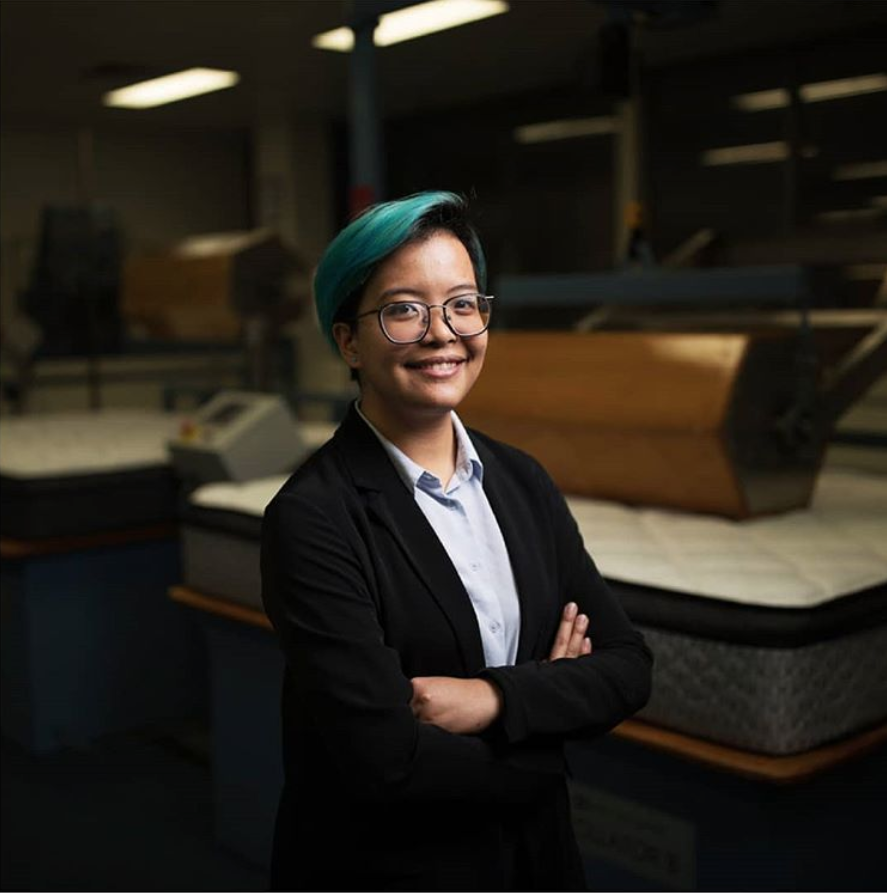

The comfort and support that Sealy mattresses are famous for is no accident. Every element is put through strenuous testing processes to ensure it meets Sealy’s non-negotiable standards, from the firmness of the mattress edge to purity of the foam. All in all, the final result is a product of 8000 hours of testing. Sealy Test and Development Engineer Alyssa Manalili takes us behind the scenes for an inside look into the making of a Sealy mattress.

Every Australian-made Sealy mattress is the product of 8000 hours of testing. These are a just few of the countless questions asked by Sealy’s research and development team.

Does it stand the test of time?

One of the fundamental qualities of a Sealy mattress is that it is made to last. “At Sealy, we are continually testing and improving, then testing again to ensure perfection,” says Sealy Test and Development Engineer Alyssa Manalili.

To test the durability of the mattresses, a Rollator barrel is rolled back and forth for more than 100,000 cycles to simulate ten years of a person sleeping on it. Unlike standard models which use a smooth barrel, the Rollator has a hexagonal-shaped edge which digs in for a more rigorous and realistic stress test.

In addition, qualitative “Sit, Feel, Try” tests are done to make sure the mattresses have the kind of feel people are looking for. “We get a sizeable number of people to test out their mattresses at home and give us their feedback, so we can fully understand what our customers want,” Alyssa explains.

“This same high level of quality assurance testing is done across the board at Sealy, whether our beds are going out to commercial clients or 5 star hotels like the Hyatt, Intercontinental, Ritz Carlton, Marriot and The Venetian,” says Alyssa. “Every mattress has to pass the same test, no matter how it’s priced or who it’s for.”

Does every element pass the test?

In pursuit of perfection, every element of a Sealy mattress undergoes rigorous testing and refining to ensure a high-quality, long-lasting product. “We have to ensure that each and every component of the mattress, including the springs, panel fabrics, comfort layers and handles, meets our standards,” Alyssa continues. “We look at the role each component plays: how supportive the springs are, how comfortable the foam is and how durable the edge support is.”

To test the unique UniCased edge support of its mattresses, Sealy uses the Cornell machine to simulate the pressure of a person sitting or lying down at the edge. This extensive testing process ensures the durability of the mattress, as well as its ability to push back against pressure. “The aim is to make sure the edges of the mattress are fortified enough to prevent anyone rolling off,” says Alyssa. “While edge support may not seem important to people who usually sleep in the middle of the bed, it matters to those with kids who sleep at the edge or mums who co-sleep with their babies.”

Does every comfort layer meet our standards?

The best mattress must not only be supportive, it must also be comfortable. At Sealy, every layer of comfort is considered. And achieving that signature comfort level is no easy task.

“We perform a strict foam quality assurance testing programme every month to look for potential impurities. Because the price of foam is based on its weight, some manufacturers in the past added chalk or clay to make their foam heavier, compromising its quality,” explains Alyssa. “We do controlled burn tests to see if there are any foreign substances in the foam and make sure we’re using only the highest quality materials.”

Sealy also works with foam suppliers, performing parallel tests and sharing best practices to promote the development of better quality materials. In order to guarantee that customers get the quality they’re paying for, nothing is left to chance.

Other monthly tests, such as foam firmness and textile durability are also performed to ensure all Sealy standards are met.

“The Sealy team shares a passion for what we do and why,” says Alyssa. “We believe in our products simply because of the numbers. The fact that we test every component and every process means that we can create mattresses that delight our customers without fail.”

Does it live up to the claim?

All these stringent testing processes take time and cost money. But Sealy believes it is worth it, not only to guarantee the highest quality mattresses for customers, but also to address the false claims in the industry.

“There are myriad mattress ads out there making grand promises that aren’t always fulfilled and customers are starting to lose faith,” says Alyssa. “We are not willing to risk losing our customers’ trust. So, our R&D team creates a test to ensure no claim is made without hard evidence to back it up, and nothing inaccurate or misleading is published. If we make a promise, we deliver.”